The infamous nylon or polyamide fabric is a favorite of fast fashion brands. Why? It’s cheap, it’s figure-hugging, can be dyed into dazzling colors and prints, and has a longer lifespan. But it’s not just the apparel industry that is taking advantage of this material. Since the emergence of polyamide, several industries have benefitted from its adaptable nature. No wonder there are different variants of polyamide, designed to cater to every product sector. But this man-made material is making the Earth pay!

Let’s delve deeper to understand what polyamide is, the types of polyamide fibres, its properties, uses, environmental impact, and more, to assess whether this fabric truly aligns with sustainability ideals and serves as a reliable choice for our clothing needs.

- What is Polyamide Fabric?

- Is Polyamide Fabric Sustainable?

- Is Polyamide Fabric Affordable?

- Polyamide Fabric Certifications

- Properties of Polyamide Fabric

- Pros & Cons of Polyamide Fabric

- Uses of Polyamide Fabric

- How to Care for Polyamide Fabric

- Famous Brands that Use Recycled-Polyamide Fabric

- Best Alternatives to Polyamide Fabric

- The Ray of Hope

- Final Thoughts…

What is Polyamide Fabric?

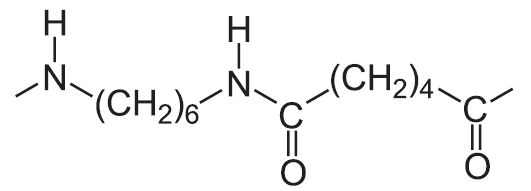

Polyamide fabric is a broad term that refers to various fabrics crafted from polyamide monomers. Made from petroleum-based plastic polymers, this synthetic textile is used for its versatility in numerous applications, including fashion. While nylon is the most recognized form of polyamide, different versions exist that are linked to related plastics like aramids and sodium polyaspartates.

What is Polyamide?

Polyamide is a type of synthetic polymer that falls under the category of engineering plastics. Also known as nylon, it’s a man-made material that has a history dating back to the early 20th century. It was first developed in the 1930s by the American company DuPont Corporation, as an alternative to silk stockings, and since then, it has been a favorite material of fashion brands and retailers. Cost-effective to produce, its remarkable attributes such as durability make it fit for cheap-priced clothing and footwear.

It was during World War II when polyamide fabrics such as nylon were used in making parachutes. Soon after the war ended, a scarcity of clothing materials led women to sew dresses by recycling parachutes. This trend popularized polyamide in women’s apparel, but using this material in its purest form lasted for a short period.

People soon realized that using pure nylon for textiles wasn’t a great idea. The fabric lacks breathability, gets damaged easily, and can melt with high heat exposure. On the contrary, when combined with other fabrics, nylon brings valuable traits like stretchiness and a smooth texture. This led to the rise of blending nylon with materials like cotton, polyester, and wool to enjoy its special advantages.

By 1945, 25% of the global textile market share constituted of artificial fabrics. But enthusiasm for nylon waned gradually. The reason? Polyamide fabrics typically originate from crude oil, and the 1970s environmental movement slowed down their production. As the novelty of fully synthetic fabrics wore off, consumers became less interested in nylon and comparable items.

In the present day, polyamide fabrics make up approximately 12% of the global production of synthetic fibers, and it is expected to decrease further over time. While polyamide originated in the United States, today, China holds the position of being the largest global manufacturer of polyamide fabrics.

Types of Polyamides

Polyamide spans a wide array of plastics priced for their affordability, resilience, and strength. The adaptability of polyamide fabrics arises from the diverse properties found in various polyamide types, rendering them valuable for a range of applications. The common grades of nylons are:

PA 66

The most popular kind of synthetic polyamide is PA 66 or Nylon 66, which was first patented by DuPont. It’s a strong and tough material belonging to the aliphatic polyamide family. Zytel is a brand of PA 66 by DuPont. Another is Technyl from DOMO Chemicals, known for its innovation and sustainability, especially Technyl 4earth version.

PA 6

PA 6 or Nylon 6 or polycaprolactam is the next common polyamide type. This form of nylon is known for its flexibility and is used in textiles and carpets due to its sturdiness and comfortable feel. Ultramid, made by BASF, is a strong, tough, and heat-resistant form of PA 6. The polyamide 6 manufactured by RadiPol (a brand by RadiciGroup) is used in yarn and textiles. Winmark Polymer Industries is an important PA 6 exporter from India.

PA 6/6

Nylon 6/6 or PA 6/6, displays exceptional strength and stiffness. It’s created through a process that involves the condensation of two monomers, giving it the “6/6” name. This type of nylon is widely used in various applications due to its robustness and durability. It finds its place in automotive parts, industrial components, and even everyday items like zippers and fasteners.

PA 12

Polyamide 12 or Nylon 12 is a flexible plastic with great mechanical and chemical qualities. It has impressive resistance to chemicals and moisture, making it perfect for specialized applications like fuel lines and hydraulic hoses. Rilsamid, a top-notch material by Arkema, is based on PA 12. It’s often used for moving fuel and in brakes.

PA 11

Polyamide 11, known as Rilsan PA11, is a high-performance polymer made entirely from renewable sources like castor oil. Produced by Arkema, it possesses impressive mechanical properties and is applied in various industries, including automotive, electronics, and industrial manufacturing.

Nylon 4

Nylon 4 stands out for its biodegradability. It is ideal for disposable items such as packaging materials or single-use products.

Nylon 66/6

The versatile Nylon 66/6 copolymer combines attributes of both Nylon 6 (PA 6) and Nylon 6/6 (PA 6/6), offering a balanced blend of strength and flexibility. It finds applications in diverse fields, from automotive components to consumer goods.

Polyphthalamids

Polyphthalamids are strong synthetic plastics, popular for replacing metals in situations requiring extreme heat resistance, such as powertrain components and electrical connectors. Trogamid, a robust polyamide from Evonik, is used in various fields like sports watches and electronics. Amodel Polyphthalamide (PPA) from Solvay is a tough polyamide, great for high temps and tough environments.

Aramids

Aramids, also known as aromatic polyamides, are super tough and heat-resistant synthetic fabrics. Kevlar, a mighty fiber from DuPont, is famous for bulletproof vests. DuPont’s Nomex brand makes fireproof suits. Teijin’s Technora is another strong, heat and chemical-resistant polyamide.

The Environmental Impact of Polyamide Production

Polyamide production has raised severe environmental concerns due to its energy-intensive processes and the requirement of specific raw materials like fossil fuels and toxic chemicals. The manufacturing of polyamides requires significant energy, contributing to high levels of greenhouse gas emissions and resource depletion. Furthermore, some raw materials used, such as petrochemicals, have major ecological implications.

To address these issues, efforts are being made where more sustainable production methods are developed. Researchers are exploring ways to use renewable resources like plant-based materials instead of petrochemicals. Additionally, recycling processes for polyamides are being refined, aiming to reduce waste and promote circular economy principles. Initiatives to create closed-loop systems for polyamide recycling are on the rise. These approaches are focused on minimizing polyamide’s environmental impact by using recycled materials and conserving resources.

What is Polyamide Fabric Made of and How it is Made?

Polyamide fabric is manufactured through the process of condensation polymerization of a plastic solution. It’s commonly produced in facilities that also manufacture other synthetic materials like nylons, polyesters, and acrylics. Polyamides are synthetic materials derived from petroleum. They are created by blending chemicals obtained from petroleum oil, which is a non-renewable resource and carries intrinsic pollution concerns.

The production process starts with combining raw materials sourced from crude oil or natural gas with hexamethylenediamine monomers (1,6-diamino hexane) and adipic acid (hexane-1,6-dicarboxylic acid). This solution is then transformed into monomers which are the building blocks of polymers.

Next, the monomers undergo polymerization, chemically bonding to form the polyamide polymer. During the condensation polymerization process, water is removed, leading to the formation of a large repeating molecule that gives rise to polyamide sheets or ribbons. These sheets or ribbons are subsequently fragmented into chips, that are melted and extruded through spinnerets to form thin fibers that are stretched in a process called drawing. This step enhances the fibers’ strength and pliability.

Lastly, weaving or knitting these fibers forms the fabric, which can be dyed for color and undergo finishing processes to boost specific properties. The final fabric is cut, sewn, and transformed into various products. The full cycle from raw material sourcing to the finished product can take several days to weeks, encompassing polymerization, extrusion, drawing, weaving/knitting, and finishing steps. Technological advancements impact the efficiency and timeline of polyamide fabric manufacturing.

Is Polyamide Fabric Sustainable?

No, polyamide fabric is not considered sustainable. And this belief is backed by some well-defended reasons. Firstly, its production heavily relies on petroleum-based materials, a non-renewable resource. Extracting and processing these resources contribute to environmental degradation and exhaust finite fossil fuel reserves. In addition, the manufacturing method of polyamide fabric involves energy-intensive techniques, releasing massive amounts of CO2 emissions and further heightening climate change.

Following from that, the production of polyamide fabric requires harsh chemicals, which, if not treated or disposed of properly, can cause a big-time threat to the ecosystems. It generates harmful byproducts and waste, contributing to pollution. Nitrous oxide (N2O) is emitted as a byproduct into the atmosphere. This potent greenhouse gas, as indicated by scientific studies, significantly contributes to the depletion of stratospheric ozone through catalytic processes. Its accumulation persists for approximately 150 years.

Nitrous oxide is significantly 300 times more powerful than carbon dioxide and exceeds the toxicity of methane by 15 times due to its capacity to trap infrared radiation. The presence of N2O in the atmosphere is rising by approximately 0.2% annually, primarily driven by the substantial rates of global adipic acid production required for the condensation polymerization of polyamides.

Furthermore, manufacturing polyamide fibers has adverse effects on human health. A large number of employees working in polyamide production sites face exposure to hazardous particles and emissions, leading to eyes, nose, throat, and skin irritation.

If that wasn’t enough, the disposal of nylon fabric or polyamide products also poses challenges as it requires decades and sometimes over a century to biodegrade. During its decomposition, polyamide releases fatal substances and gases into the surroundings. Such artificial textiles disrupt ecosystems along with adding to volumes of discarded clothing deposited in landfills annually. Moreover, polyamide fabric discharges plastic microfibers, which contaminate whole food chains while killing land and marine animals and posing risks to human well-being.

Is Polyamide Fabric Affordable?

Yes, polyamide fabric is affordable compared to many natural fibers like organic cotton, hemp, linen, etc., and that’s one of the prime reasons for its widespread use in the textile industry. Manufacturing nylon is less costly than the agricultural processes required for the cultivation of organic natural materials. The same is the case with other semi-synthetic fabrics like lyocell or modal that are produced under responsible closed-loop processes.

Of course, the affordability of polyamide fabric can vary based on factors such as production methods, brand, and quality, but it is favored by fast fashion brands solely for the fact that they can make cheaper clothes out of it.

Polyamide Fabric Certifications

The majority of polyamide fabrics undergo various assessments to ascertain their quality, yet no official certifications are presently allocated to this synthetic material. However, recycled polyamide might possess certifications from recognized third-party entities like-

- Global Organic Textile Standard (GOTS)

- Recycled Claim Standard (RCS)

- Global Recycled Standard (GRS)

Properties of Polyamide Fabric

- Polyamide fabric has high tensile strength, which makes it durable and long-lasting.

- It is versatile for different weather conditions.

- Polyamide fabric is resistant to insects, moths, molds, fungi, and a range of common chemicals.

- It is usually treated to be water-resistant.

- Depending on the processing technique, nylon fabric can have varied shine, finish, and feel on the skin.

- It is stain-resistant.

- Polyamide is stiff, meaning it is low on shrinkage even after washing and drying multiple times.

- It can be easily dyed in vibrant shades, and the risk of color bleeding during washing is minimal.

- Nylon fibers typically do not withstand harsh chemicals. It will dissolve in substances like phenol, acids, and various other compounds.

- It lacks resistance to sunlight or UV deterioration. When exposed to direct sunlight, polyamide’s physical and chemical characteristics tend to deteriorate rapidly.

- It is lightweight but not really breathable.

- Polyamide fabric is one of the top choices for activewear and swimwear because of its waterproof, moisture-absorbing, and quick-drying features.

- It is an easy-to-maintain clothing material.

Pros & Cons of Polyamide Fabric

Pros

- Polyamide fabric has good tenacity and resilience that extends its longevity.

- It has good abrasion resistance.

- It is resistant to moths and mildews.

- It dries rapidly, which is especially advantageous for activewear and outdoor use.

- Nylon fabric doesn’t shrink after washing and drying.

- It is water-repellant and has moisture-wicking qualities.

- It catches dyes easily.

- It is wrinkle-resistant.

- Polyamide fabric offers flexibility and easy movement due to its good stretchability.

- It is affordable.

- It is a versatile material that can be used in various clothing items, accessories, and industrial applications.

Cons

- Polyamide production involves finite resources, leading to pollution and environmental degradation.

- The production process requires a considerable amount of energy input and emits pollutants.

- This material can’t be kept under strong sunlight for hours as it is susceptible to damage when exposed to sunlight or UV radiation.

- Depending on the weave, blend, and treatment, it will have lower breathability than natural fibers.

- It melts under high temperatures, which limits its application in high-heat environments.

- Polyamide fabric is prone to static electricity buildup, causing discomfort for some wearers.

- It is not suitable for all skin types. Some individuals may experience skin allergies or discomfort due to its synthetic nature.

- It is not resistant to odors.

- Clothing made from nylon might develop pilling or fuzziness over time, affecting appearance.

- Its water-intensive production process can strain local water bodies.

Uses of Polyamide Fabric

- Polyamide fabric is used in the apparel and fashion sector for designing activewear, swimwear, tops, leggings, undergarments, hosiery, and so on.

- In industrial settings, polyamide fabric is utilized in automotive components, aerospace interiors, and sports equipment due to its strength and durability. It is used in making ropes, conveyor belts, hydraulic hoses, filters, and more.

- It has found its way into medical applications like sutures and dressings due to its biocompatibility.

- Home textiles such as bedding and upholstery benefit from polyamide’s toughness, while outdoor gear like backpacks, tents, and camping gear rely on its weather-resistance properties.

How to Care for Polyamide Fabric

Caring for garments made from polyamide fabric is easy. You just need to pay a little attention to retain their quality and longevity. Here’s how to care for them:

- Use a gentle cycle with cold water to wash polyamide garments. Avoid using hot water, as it can damage the fabric’s fibers. Turn the garments inside out before washing to prevent friction and pilling.

- Use a mild detergent. Avoid using bleach or harsh chemicals, as they can weaken the fabric’s fibers.

- Don’t overload the washing machine with too many polyamide garments. This can cause friction and lead to pilling or damage.

- If possible, hand wash the garments in cold water using a gentle detergent. Gently agitate the water to clean the fabric and avoid wringing or twisting to prevent stretching.

- Air-dry polyamide garments by laying them flat on a clean towel or drying rack. Avoid hanging them for long hours, as the weight of the water can stretch the fabric. Keep them away from direct sunlight to prevent fading.

- Most polyamide fabrics don’t require ironing, as they are wrinkle-resistant. However, if needed, use a low heat setting and place a cloth between the iron and the fabric to prevent direct contact.

- Store these synthetic garments in a cool, dry place. Avoid hanging heavy items on them.

- Some polyamide fabrics have special features like water resistance or UV protection. Follow the care instructions provided by the manufacturer for such garments to maintain their functionality.

- Address stains promptly by blotting, not rubbing, with a clean cloth. If needed, spot-clean the stain using a mild detergent and cold water. Test a small, hidden area first to ensure it doesn’t affect the color or texture.

- Always check the care label on each garment for specific care instructions, as different blends and finishes might have unique requirements.

Famous Brands that Use Recycled-Polyamide Fabric

Best Alternatives to Polyamide Fabric

Hemp

Hemp is a natural fabric crafted from the fibers of the hemp plant, making it highly sustainable due to its minimal water and pesticide requirements. It’s highly adaptable and used for clothing, accessories, and home textiles. Hemp is durable, breathable, antibacterial, and naturally UV-resistant, providing comfort in every weather condition. Its cultivation enriches the soil and requires less water than other crops, making it one of the lowest-impact fabrics.

Linen

Linen comes from the flax plant, which requires the least care and resources for harvest. It is the perfect natural fabric, particularly for clothing, and bedding. It’s breathable, moisture-wicking, hypoallergenic, super-comfy, and has a natural luster. Linen production requires less water and pesticides, and flax cultivation enhances soil health. Plus, linen’s biodegradability and long lifespan contribute to its low environmental impact.

Lyocell

Lyocell, a type of rayon, is derived from sustainably harvested wood pulp, often sourced from eucalyptus or beech trees. Lyocell is used for creating garments and home textiles. It’s silky, moisture-wicking, breathable, and suits even sensitive skin types. The closed-loop production process used in lyocell manufacturing is designed to reduce water and chemical use, making it an environmentally friendly fabric.

Modal

Modal is another type of rayon, made from beech tree pulp. It’s used for apparel, undergarments, and activewear. This fabric is lightweight, soft, drapes well, amazingly breathable, and offers moisture-absorbing features. The production process is resource-efficient, with less water and energy consumption compared to conventional textiles.

EcoVero

EcoVero is a variant of viscose made from certified renewable wood sources, with a lower environmental impact. Used in clothing and textiles, EcoVero has good tenacity, is gentle on the skin, hypoallergenic, and biodegradable. Its manufacturing process is built to responsibly reduce emissions and water usage, making it an eco-conscious choice.

The Ray of Hope

While polyamide fabric has faced criticism for its negative impact on the planet, there’s hope to fix this issue. Proper recycling practices can significantly cut its carbon footprint. Innovations in textile recycling technology are emerging, offering the potential to transform discarded polyamide products like fishing nets, post-consumer waste, etc., into new materials.

In fact, Aquafil is one such company producing Econyl fabric— recycled nylon. The materials consist of regenerated fibers sourced from discarded plastics, carpet flooring, industrial waste, and so on. For every 10,000 tons of Econyl material, approximately 70,000 barrels of crude oil and 57,100 tonnes of CO2 emissions can be preserved. It lowers nylon’s influence on global warming by around 80% in comparison to other raw materials derived from oil.

With such efforts towards responsible recycling, corporations and regulatory bodies can mitigate the environmental challenges associated with polyamide fabric.

Advancements in Sustainable Production

Despite the challenges posed by polyamide fabric’s detrimental effects, ongoing research and innovations in textile production hold the promise of more sustainable methods. Advancements in chemical processes and recycling techniques are being explored to reduce the negative footprint of polyamide manufacturing. Researchers are focusing on developing bio-based sources for polyamides, utilizing renewable materials like plant-based polymers. Additionally, cutting-edge recycling infrastructures are being developed for the suitable breakdown of polyamides to create new materials, thus, channeling a circular approach. These initiatives highlight the industry’s dedication to improving the sustainability of polyamide fabric, offering hope for a greener future.

Bio-based Polyamides

The rise of natural polyamides derived from renewable sources like plant-based materials presents a promising shift in the textile industry. These alternatives have the potential to visibly diminish the dependence on fossil fuels, thereby reducing the ecological impact associated with petroleum-derived polyamides. While many bio-based options are still in the early stages of development, leading brands are actively investing in their research and development. Initiatives such as Textile Exchange’s Biosynthetics Working Group and collaborations with entities like Fashion for Good reinforce the collective effort within the industry to explore and enhance the sustainability of these alternatives. Through these innovations, the textile sector aims to forge a more eco-friendly path for polyamide production.

Recycling Technology

The evolution of recycling infrastructure has led to advanced methods for efficiently repurposing used polyamide fabrics. These technologies focus on transforming discarded polyamide textiles into new fibers, minimizing waste and environmental impact. Closed-loop recycling systems play a pivotal role in achieving a circular economy, where rejected polyamide-made items are collected, processed, and reconverted into usable materials. In these techniques, nylon products like garments, fishing nets, etc., are sorted, cleaned, and chemically treated to break down the fibers into their original monomers. The monomers are then used to create new polyamide fibers, offering a sustainable solution to the textile waste issue. As these recycling technologies continue to develop, they offer they hopeful solutions to tackle polyamide fabric’s sustainability concerns, promoting responsible textile production.

Microfiber Solutions

Efforts to address microfiber pollution are ongoing, with a focus on fabricating innovative fabrics specially designed to shed fewer microfibers during the washing process. These innovative textiles strive to deal with the root cause of microfiber pollution by minimizing the release of these tiny particles. Additionally, filtration systems and washing machine accessories have also been introduced to capture released microfibers, preventing them from entering waterways. These technologies not only help curb the environmental impact of microfiber pollution but also encourage consumers to adopt more sustainable laundering practices.

Eco-friendly Dyeing and Finishing

Conscious polyamide manufacturers have started to implement sustainable dyeing and finishing processes to make the lowest impact on the planet. These methods focus on cutting water consumption and the use of harmful chemicals. Cutting-edge technologies are being employed to achieve vibrant colors of these fabrics without compromising the environment’s welfare. These approaches not only lessen the effects of synthetic textiles but also contribute to forming a cleaner, more accountable textile industry.

Consumer Awareness and Choice

Informed consumer choices have the power to steer demand towards sustainable products, including green polyamide fabrics. As consumers become more educated about the environmental impact of their purchases, their preferences lean towards sustainable materials. This heightened demand for eco-friendly options exerts pressure on manufacturers to adopt greener business practices throughout their supply chains. In response to this shift, companies are compelled to incorporate sustainable materials, production methods, and transparent sourcing into their operations. This shift not only helps in meeting consumer preferences but also aligns with the broader global movement of creating a pollution-free future.

Collaborative Initiatives

Partnerships between brands, researchers, and environmental organizations are playing a crucial role in advancing the sustainability of polyamide fabric. This approach brings together diverse expertise and resources to collectively address the environmental challenges linked to polyamide production. Through such joint efforts, they can share knowledge, explore innovative technologies, sustainable sourcing practices, and responsible production methods to keep a check on polyamide’s negative aspects. As brands have started to recognize the importance of responsible production, these collaborations serve as platforms for designing a more eco-friendly nature of polyamide fabric.

Government Regulations and Incentives

There is a pressing need for stronger government regulations to encourage textile manufacturers to adopt greener practices. By imposing standards and requirements for sustainable production, governments can directly announce an eco-friendly level that every textile corporation needs to abide by. Incentives such as tax breaks, grants, and subsidies further motivate companies to invest in resource-efficient technologies and materials. These measures not only ensure compliance with sustainable norms but also promote innovation, research, and development of greener technologies. As a result, textile producers prioritize responsible processes and better business habits.

Final Thoughts…

While polyamide fabric offers durability and affordability, its aftermath on the planet is alarming. Its production process is filthy and hazardous; it takes decades to break down, pollutes the air, soil, and water, and has a plastic feel that lacks breathability. So definitely, not something you would enjoy wearing for long hours. It’s true that polyamide can be recycled endlessly, reducing the need for new resources, but recycling is expensive, which is why brands keep producing virgin nylon.

The good news is sustainable alternatives to polyamide exists that are not only safe for your skin but also for Mother Earth’s well-being. Numerous ethical fashion brands and designers globally have already opted to avoid using polyamide fabric altogether. Now it’s your turn to make the wiser choice! Ditch those plastic-based materials and support sustainable brands to enjoy the benefits of natural and responsibly-made fabrics.