Acetate fabric stands as the United States’ second-oldest manufactured fiber after rayon. As an affordable alternative to silk, the material is celebrated for its lustrous sheen, making it a staple in creating exquisite attires such as graduation gowns, prom dresses, bridal wear, and more. With wood pulp as its primary raw material, acetate bears similarities with many semi-synthetic textiles like viscose, lyocell, and modal. But the existence of this beautiful fabric has a seemingly dark outcome on the planet’s well-being.

Despite being a popular textile, the nitty gritty of acetate remains unknown to many. As the demand for eco-friendly materials increases, will this fabric be able to pass the green test? Let’s learn more about acetate, unravel its unique properties, weigh its pros and cons, and investigate its sustainability quotient.

- What is Acetate Fabric?

- Is Acetate Fabric Sustainable?

- Is Acetate Fabric Affordable?

- Acetate Fabric Certifications

- Properties of Acetate Fabric

- Pros & Cons of Acetate Fabric

- Uses of Acetate Fabric

- How to Care for Acetate Fabric

- Famous Brands that Use Acetate Fabric

- Best Alternatives to Acetate Fabric

- Concluding Thoughts…

What is Acetate Fabric?

Acetate fabric, also known as cellulose acetate, is a type of semi-synthetic material known for its elegant appearance and glossy finish. It is composed of cellulose fibers that are chemically treated to create a material with a silk-like texture and sheen. This fabric is lightweight, drapes beautifully, and is often used to create garments with a luxurious look. Although it’s made from wood pulp— a natural and renewable raw material, acetate fabric is considered as a semi-synthetic fiber due to its chemical-infused manufacturing process.

The history of acetate fabric dates back to 19th-century Europe. It was first developed by French chemist Paul Schützenberger in 1865 as a varnish for airplane wings. Later, it was introduced as a fabric in the U.S. in 1924. The pioneering work in developing the form of acetate fabric was carried out by Swiss chemist Camille Dreyfus, who patented the process in the 1920s. The company Celanese Corporation played a significant role in commercializing acetate fabric in the United States.

Today, the leading producers of acetate fibers include Eastman Chemical Company (US), Daicel Corporation (Japan), and Celanese Corporation (US). These textile manufacturers continue to refine the production process to create high-quality acetate fabrics that cater to the demands of modern fashion and design.

What is Acetate Fabric Made of and How is it Made?

Acetate fabric is primarily made of cellulose from wood pulp, specifically from softwood trees like spruce and pine. It belongs to the rayon family, and production involves several steps. The acetate production process starts with chemically treating wood pulp with acetic acid (vinegar), acetic anhydride, sulfuric acid, and acetone to create cellulose acetate. This substance is then dissolved in a solvent to form a thick syrupy liquid. This solution is then forced through tiny holes of spinnerets to create fine filaments of cellulose acetate, which are solidified through coagulation in a chemical bath.

Acetate fiber is manufactured using the wet spinning method, similar to other synthetic fibers like nylon and acrylic. The resulting filaments are then washed, dried, stretched, and spun into yarns, ready to be dyed and weaved for different uses.

The entire manufacturing process, from sourcing raw materials to obtaining finished acetate yarn, takes several days. The sourcing of wood pulp, the chemical treatment, the spinning of filaments, and subsequent processing are all time-consuming steps that contribute to the overall production timeline. The final product is a versatile and luxurious fabric known for its lustrous appearance and smooth texture, often used in clothing and various textile applications.

Do keep in mind that different form of cellulose acetate fibers exist, like acetate nylon, acetate rayon, satin acetate, or acetate viscose. Each variation possesses distinct characteristics and uses.

Is Acetate Fabric Sustainable?

No, acetate fabric is not at all sustainable. The production process of this man-made fiber involves a plethora of toxic chemicals, which can be hazardous to the environment and human health. Plasticizers made from petroleum are also a part of the composition, including the extensively debated and poisonous phthalates, which contribute to various health problems affecting both general and reproductive well-being. These chemical additives pose serious risks not only to the consumers but also to workers exposed during manufacturing, the surrounding environment, and wildlife.

Adding to the concern, acetate can potentially add to microplastic pollution. In fact, it has been identified as one of the seven materials responsible for over 50% of the microplastics discovered in the Arctic.

Furthermore, sourcing wood pulp for acetate involves deforestation and impacts biodiversity. The manufacturing process itself is resource-intensive, requiring significant amounts of water and energy. What’s worse, acetate fabrics have low durability and tend to wrinkle easily, leading to shorter lifespans and increased waste. These factors contribute to acetate fiber’s negative environmental impact, giving you enough reason to avoid it.

But if you prefer to use this material, opting for bio-acetate, which is a plant-based version, is a good idea. It is derived from renewable sources such as wood pulp and manufactured under eco-friendly processes using biodegradable plant-based plasticizers. Bio-acetate aims to address some of the environmental concerns associated with conventional acetate production, such as the use of toxic chemicals, the release of harmful pollutants, and low biodegradability.

Is Acetate Fabric Affordable?

Yes, acetate fabric is way more affordable than its alternatives like silk, lyocell, and certain types of rayon. This cost-effectiveness is actually one of the chief reasons for its widespread usage. Because there’s plenty of cellulose, manufacturing this fabric is cheap. And reduced manufacturing expenses ultimately lead to more budget-friendly retail prices, ensuring accessibility for a wide range of consumers.

Cellulose acetate fibres are commonly blended with various other synthetic and natural yarns like nylon, cotton, wool, silk, etc., to cut on raw material costs. Many global fashion brands and designers use this fabric to craft budget-friendly and moderately priced clothing. It is a hot-favorite of fast fashion brands as it can be easily utilized in mass-producing inexpensive garments being either the main fiber or a significant portion of the fabric composition.

Although it may offer economic benefits, its recommended to carefully assess its overall affordability by taking into account the detrimental environmental consequences and potential health hazards linked to its production and disposal.

Acetate Fabric Certifications

Properties of Acetate Fabric

- Acetate fabric has a smooth and silky texture, resembling natural silk.

- It is lightweight and has a luxurious appearance.

- It can be easily dyed to a range of colors and prints.

- Acetate is a soft fabric that exhibits superb drapeability.

- It is pleasant to the touch.

- With low moisture absorption, acetate dries relatively quickly.

- Pilling is minimal, and static is less of an issue.

- It has limited stretch compared to elastane-based fabrics.

- Cellulose acetate is generally not waterproof.

- It is susceptible to staining, especially with oil-based substances, crayon stains, and more.

- Prone to shrinking when exposed to high heat or improper washing.

- It is resistant to moths, mildew, and fungi.

- Most acetate garments require to be dry-cleaned.

Pros & Cons of Acetate Fabric

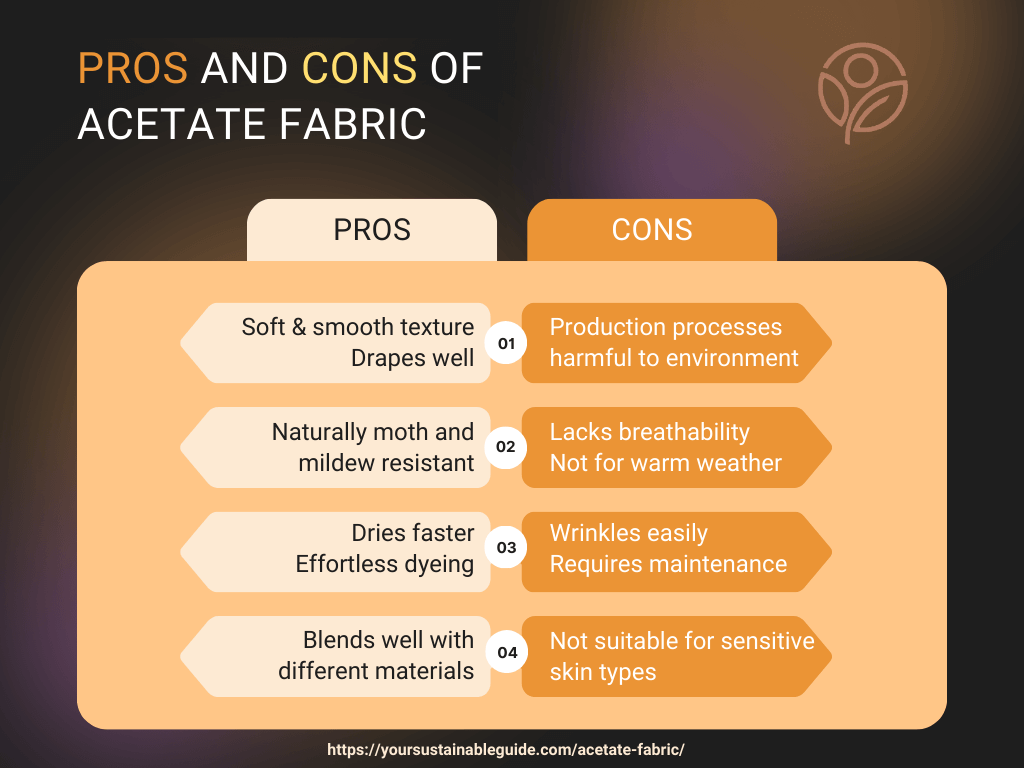

Pros

- Acetate is loved for being a shiny fabric. It exhibits that gorgeous silk-like appearance, because of which it is widely used in designing party attires, bridal wear, prom dresses, etc.

- It drapes well and has a soft, smooth texture.

- Acetate material is naturally moth and mildew resistant.

- It has relatively low moisture absorbency, leading to faster drying times.

- Acetate fabric doesn’t have pilling issues.

- It generates less static compared to other synthetic fabrics.

- It can be effortlessly dyed into any choice of colors.

- The tactile sensation of acetate is pleasant on the skin.

- Acetate blends well with different types of materials.

- It is affordable.

Cons

- Acetate fabric lacks breathability, making it uncomfortable to wear in warm weather.

- It is sensitive to high temperatures and can easily melt or shrink when exposed to heat.

- It has a tendency to wrinkle easily, requiring careful maintenance.

- Acetate is a delicate fabric which makes it less durable and prone to wear and tear.

- The production process involves strong chemicals that are harmful to the environment and contribute to microplastic pollution.

- Most acetate garments need dry cleaning, adding to maintenance costs.

- Over time, acetate fabric can degrade and lose its original qualities.

- It is not resistant to stains.

- It has low abrasion resistance.

- It gathers static electricity.

- It is not suitable for sensitive skin types, as it might cause discomfort.

Uses of Acetate Fabric

- Acetate fabric is used in creating partywear costumes like evening attires, wedding dresses, and formal dresses due to its elegant drape and shiny appearance. Different blends of acetate have their unique aesthetic, because of which they are used in making hats, scarves, suits, ties, sweaters, formal tops, and coats. Its soft silk-like texture makes it suitable for lingerie and sleepwear items.

- Apart from apparel, acetate fabric finds utility in home textiles like draperies, upholstery, curtains, carpets, and various other home décor items that require this specific type of textile.

- Acetate’s vibrant colors and sheen make it a choice for craft projects, including ribbon making, trims, and embellishments.

- Beyond home textiles and clothing, this man-made cellulosic fiber’s versatile properties were used for crafting cigarette filters for decades, along with eyewear frames.

How to Care for Acetate Fabric

- Examine the care label to determine if washing is suitable for the acetate fabric. Some labels indicate “Dry Clean Only,” while others may advise against dry cleaning, depending on the fabric blend.

- Opt for cold water and a gentle wash cycle type during the cleaning process to prevent damage.

- Gently handwash without agitating the fabric, and use mild detergents.

- Air-dry in a clothing line outside. But avoid prolonged exposure to direct sunlight because it is sensitive to UV rays and can become discolored or weakened. Don’t use the dryer, as excessive heat can lead to the melting of the fabric.

- Hang or fold acetate garments properly to prevent creasing and wrinkles. low heat if necessary,

- Consider ironing to remove creases only if it is recommended in the product care instructions. Iron on a low-heat setting using a pressing cloth to be extra careful.

- Exercise caution with acetate fabric around chemicals like perfumes, specific glues, and nail polish removers, as they can potentially cause melting or damage.

- Store acetate garments in a cool, dry place and keep away from placing heavy items on top of them.

Famous Brands that Use Acetate Fabric

Best Alternatives to Acetate Fabric

Lyocell

Lyocell fabric or Tencel lyocell is a semi-synthetic fiber composed of wood pulp, commonly sourced from eucalyptus or beech trees. It offers a silky smooth texture, exceptional breathability, and moisture absorption, making it ideal for clothing, bedding, and activewear. It is also antibacterial and 100% biodegradable. Lyocell is produced in a closed-loop process, where solvents are recycled to eliminate chemical waste.

Modal

Modal fabric is a form of rayon made from the cellulose of beech trees. It is lightweight, breathable, has amazing softness, drapeability, and color retention properties. Modal is used in various clothing items, including loungewear, underwear, and casualwear. Its production requires less water and resources compared to acetate, making it more sustainable.

EcoVero

Lenzing EcoVero is an upgraded variation of viscose made from sustainably sourced certified wood and produced using environmentally friendly processes. The fabric drapes well, has a soft feel along with being hypoallergenic and is super breathable making it ideal for garments like dresses, shirts, and scarves. EcoVero production reduces water and fossil fuel consumption, earning it a lower carbon footprint.

Cupro

Cupro is made from cotton linter— a byproduct of cotton production. It is an alternative to silk and offers a rich shine with buttery touch and excellent breathability. Apart from being used in designing dresses, it is often utilized in linings, lingerie, and accessories. Cupro’s production utilizes cotton waste, making it resource-efficient. While its production process is not entirely low-impact, it minimizes waste and is definitely better than acetate.

Concluding Thoughts…

Acetate offers certain advantages in terms of its feel, appearance, and affordability that are too hard to ignore for people on the lookout of reasonably-priced sleek-looking fabrics. But the environmental and health hazards that come with this material can’t be overlooked. The production of acetate is often linked to deforestation, pollution, and wasteful processes that destroy ecosystems. As we become more conscious of the impact of our clothing choices, it’s important to consider textile alternatives that are truly sustainable and eco-friendly.

But if you have a preference for acetate fabric and want to enjoy it, then do so responsibly by choosing bio-acetate, which is a greener option. The shift towards bio acetates is advancing rapidly, driven by conscious consumers’ desires and awareness regarding the detrimental additives in acetate. Research and development endeavors are also focused on enhancing its sustainability. So if acetate has to stay, it should well be bio-acetate, that too, certified by FSC, PEFC, or other regulatory bodies.